What is Vectran? When we talk about Vectran fiber, we refer to a high-performance multifilament yarn spurn from liquid crystal polymer, created by Celanese and produced from Kuraray since 2005.

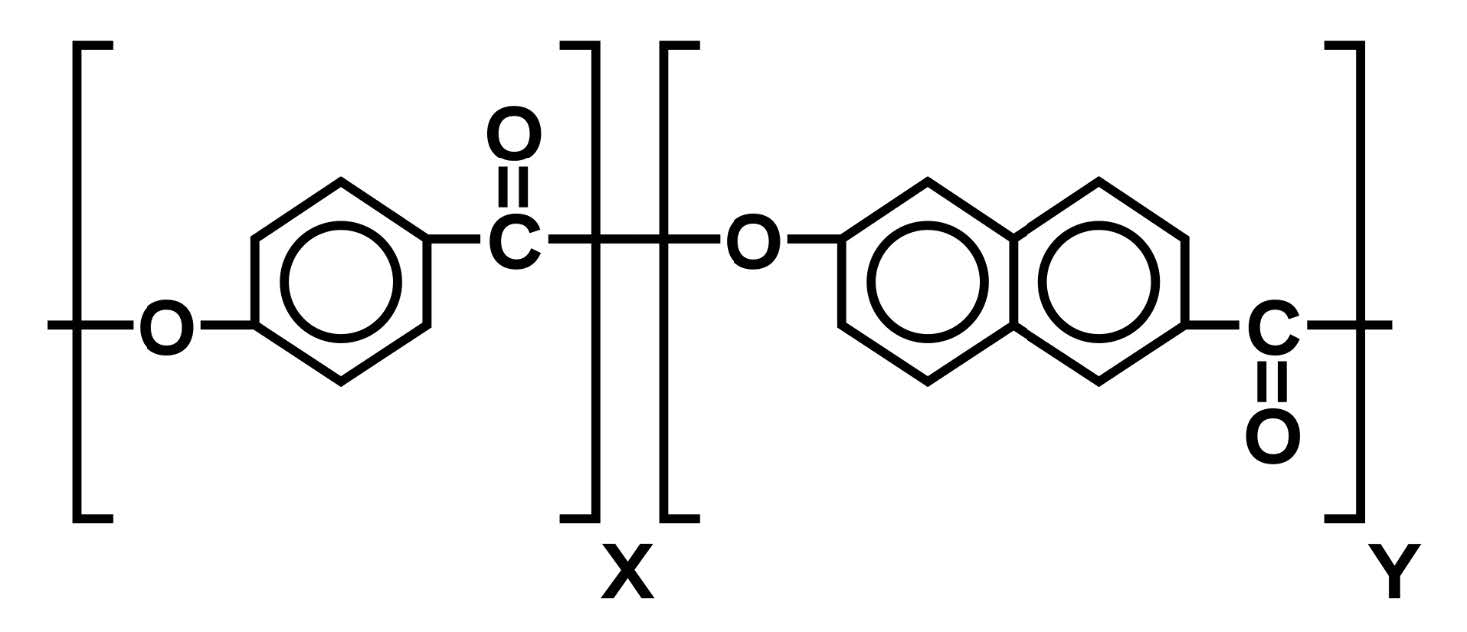

Looking at its chemical structure, it is an aromatic polyester produced by the polycondensation of 4-hydroxybenzoic acid and 6-hydroxynaphthalene-2-carboxylic acid. This leads to some advantages that make Vectran an extremely technical fiber, characterized by an exceptional strength and rigidity: the best choice between the more famous Ultra High Molecular weight PolyEthylene fibers (UHMW PE) and Para-aramid fibers.

Due to these characteristics, this material is suitable for a wide range of applications in many different fields, from the production of ropes to aerospace.

Properties: a strong and high-performing fiber

What are the main characteristics of Vectran? This material is not only extremely strong, but also particularly stable and resistant to flex fatigue and abrasion.

Indeed, Vectran has a broad variety of characteristics, including an excellent resistance to abrasions, creeps, cuts, chemicals, solvents, ultraviolet light and high-temperatures. Moreover it has an exceptional flex fatigue, bending resistance and a low coefficient of thermal expansion, maintaining its original sizes if subjected to change in temperature.

Talking about its capacity to release gas vapors, Vectran shows a minimal moisture absorption, which guarantees great durability as a fiber.

In conclusion, Vectran has high dielectric strength, high impact strength and vibration damping characteristics.

The main applications and uses of Vectran

As a company, TAY srl is proud to produce stretch broken yarns and composite yarns using 100% of Vectran or mixed with other fibers or filaments.

Actually, the characteristics of Vectran fiber give us the opportunity to produce a yarn with a very high tenacity (20% more in comparison with the same produced with 100% aramid) and cut resistance, but with better thermal properties than the traditional UHMW PE.

Over the years we’ve developed and expanded the production of this fiber and, at present, our Vectran yarns are used in different applications.

First of all, it is used to produce anti-cut and vandalism fabrics for transportation. In fact, Vectran exhibits high LOI (Limit Oxygen Index) values of 30%, that is comparable to the traditional aramid, but with a better cut resistance in knit and woven fabrics.

Secondly, Vectran is used to make ropes and narrow fabrics. Flexural fatigue is a critical concern in many applications where the yarns and fabrics are subjected to repeated bending or creasing. Using Vectran fiber, the loss in tenacity at failure locations after 100 cycles is only 0,8%.

Lastly, we use this high-performing fiber also in aerospace applications. Actually, in July 1997, the Mars Pathfinder made its historical landing on the surface of Mars, cushioned by airbags made of Vectran fiber.

If you need further information about our Vectran yarns or you want to know if it is the best solution for your application, please contact us.

Our experts in the development and production of high value and performance yarns are available to answer your questions.