The chemist Stephanie Kwolek (1923–2014) was born in New Kensington, Pennsylvania.

Her father, who died when she was 10 years old, was a naturalist by avocation. She spent many hours with him exploring the woods and fields near her home and filling scrapbooks with leaves, wildflowers, seeds, grasses and detailed descriptions. From her mother, at first a housewife and then by necessity a career woman, Kwolek inherited the love for fabrics and sewing.

After receiving her bachelor’s degree with a major in chemistry from Margaret Morrison Carnegie College of Carnegie Mellon University in 1946, she applied for a job as a chemist with the DuPont Company, among other places.

The invention of Kevlar

Kwolek was in her 40s when she was asked by DuPont to scout for the next generation of fibers capable of performing in extreme conditions. This assignment involved preparing intermediates, synthesizing aromatic polyamides of high molecular weight, dissolving the polyamides in solvents, and spinning these solutions into fibers.

She unexpectedly discovered that, under certain conditions, large numbers of the molecules of these rodlike polyamides become lined up in parallel, that is, form liquid crystalline solutions, and that these solutions can be spun directly into oriented fibers of very high strength and stiffness. These polyamide solutions were unlike any polymer solutions previously prepared in the laboratory. They were unusually fluid, turbid, and buttermilk-like in appearance, and became opalescent when stirred.

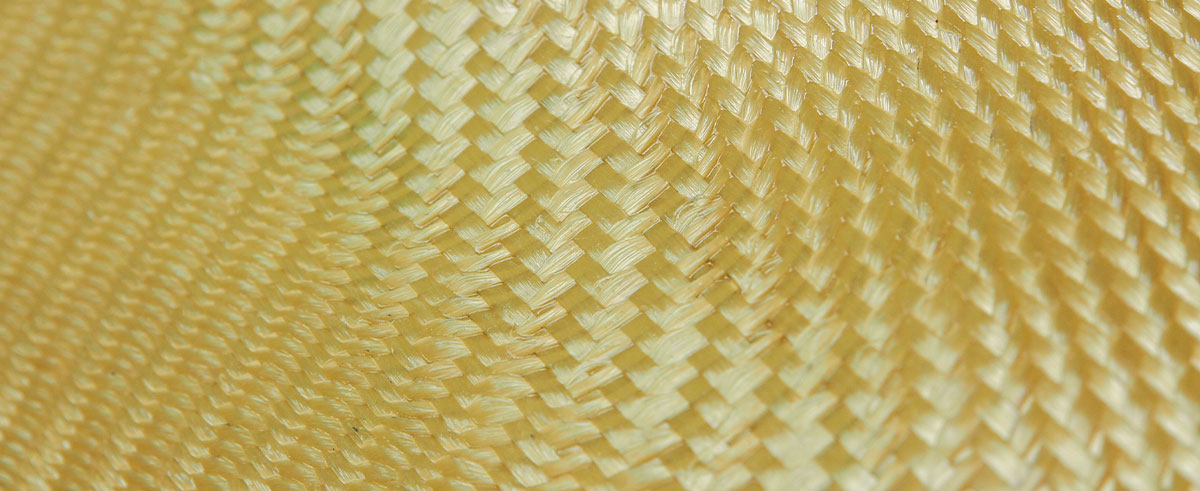

The person in charge of the spinning equipment initially refused to spin the first such solution because he feared that the turbidity was caused by the presence of particles that would plug the tiny holes (0.001 inch in diameter) in the spinneret. He was finally persuaded to spin, and much to his surprise, strong, stiff fibers were obtained with no difficulty. Following this breakthrough, many fibers were spun from liquid crystalline solutions, including the yellow Kevlar fiber.

Why Kevlar: a durable, strong and innovative fiber

Kevlar is nowadays one of the most recognized fibers in the world of protection.

Unlike other fibers, Kevlar can offer not only a great tenacity and cut withstanding, but also a very high heat resistance. For this matter, today it is used in many markets and advanced-technology applications, meeting a broad range of uses, including Personal Protection Equipment solutions, automotive and aerospace.

The manufacturing process of Kevlar

As a company, at TAY we use Kevlar as a raw material for the production of our yarn.

Thanks to our spinning and twisting technology we are able to increase and customize the already extreme performances of Kevlar fiber. Sewing threads, yarns for fireproof fabrics, and anti-cut yarns are some of the products in which Kevlar is used today.