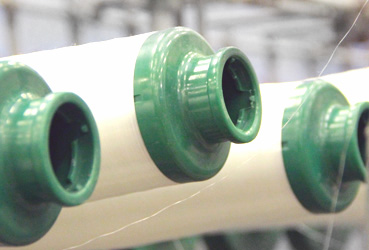

Continuous filament twisting technology

Continuous filament twisting deeply influences yarn properties, such as strength and softness

The continuous filaments that are normally produced flat can be twisted, plied and rewound in order to obtain the right count and the optimal workability during the textile process. A combination of different raw materials or a change in the level of twist can deeply influence many yarn properties, such as strength and softness.

Continuous filament is extruded as one long string. These strings are then twisted, plied and rewound together to form strands of yarn. The yarn may also be texturized to curl, or kink; this also increases the bulk and gives the yarn twist more memory for better texture retention and wear resistance.

Our experience in continuous filament twisting technology

For any application there is a specific yarn, just twisted, plyed or mixed with Elastane for increase the comfort. With this method we can find the exactly technical workability you need.

Advantages of continuous filaments twisting system

- Optimal workability

- Possibility to be twisted

- Possibility to be plied

- Possibility to be rewound

Raw materials

Thanks to our technical experience in continuous filament twisting system, we are able to works lots of fibers with this kind of tecnology, as: Glass, Inox, Copper, Para-aramide, and original fiber as Twaron®, Kevlar®, Technora®, Vectran®, Spectra®.

We also use this process with these raw materials: Elastane, Polyamide and Polyester, in order to obtain best performance for our customer and for being constantly updated on the market request