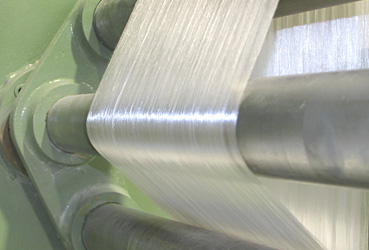

Stretch broken spinning system

Very high tenacity, low pilling, low hairiness and high fatigue resistance yarns.

The fibers produced and spun with the stretch broken spinning system are longer than the other fibers obtained with traditional spinning system, the result is a yarn with a very high tenacity, low pilling, low hairiness and high fatigue resistance.

Stretch broken spinning system has many advantages. First of all, the technical yarns, results of this process, has a high level of tenacity, resistance to abrasion, cut and heat resistant and, in the meantime, suitable for the production of technical workwear and sportswear clothing. High performances is perfectly combined with wearability and great comfort.

Our experience in Stretch broken spinning system

We are leader in stretch broken spinning system solutions. We created this process during years and we improve our knowledge every day, using new methods, new materials, and improving the performances of our yarn.

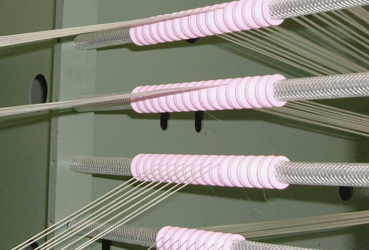

Advantages of stretch broken spinning system yarns

- Longer fiber than traditional spinning

- Very high tenacity

- Low pilling

- Low hairiness

- High fatigue resistance

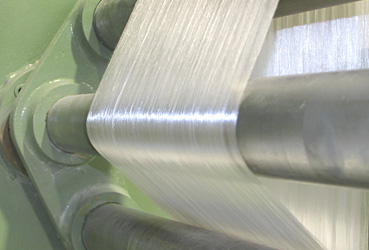

Raw materials

Thanks to our technical experience in stretch broken system, we are able to works lots of fibers with this kind of tecnology, as:

Twaron®

Kevlar®

Conex®

Panox®

Pyron®

Polyamide

UHMW PE

Spectra®

Technora®